Mini Stache

The challenge of this injection molding project was to design an object within carefully defined parameters for part thickness and profile. The part needed to fit within a 2x3 in mini mold and have specified ejector pin holes. The greater focus of this project was to learn how to operate an Arburg Press and design an effective gate and runner.

The mustache was molded with white and mint green color pellets in HDPE. The previous machine operator molded with red pellets, which entirely overpowered the white color and resulted in a transition from red to pink to green.

Design Concept

I thought my facial hair was destined for greatness the first time I shaved my face in sixth grade. I was wrong. This is not to say I have not made gallant attempts. In a family of mustached men, it takes a great deal of courage to live with mangy facial scruff. Here’s to the mustache I could never grow.

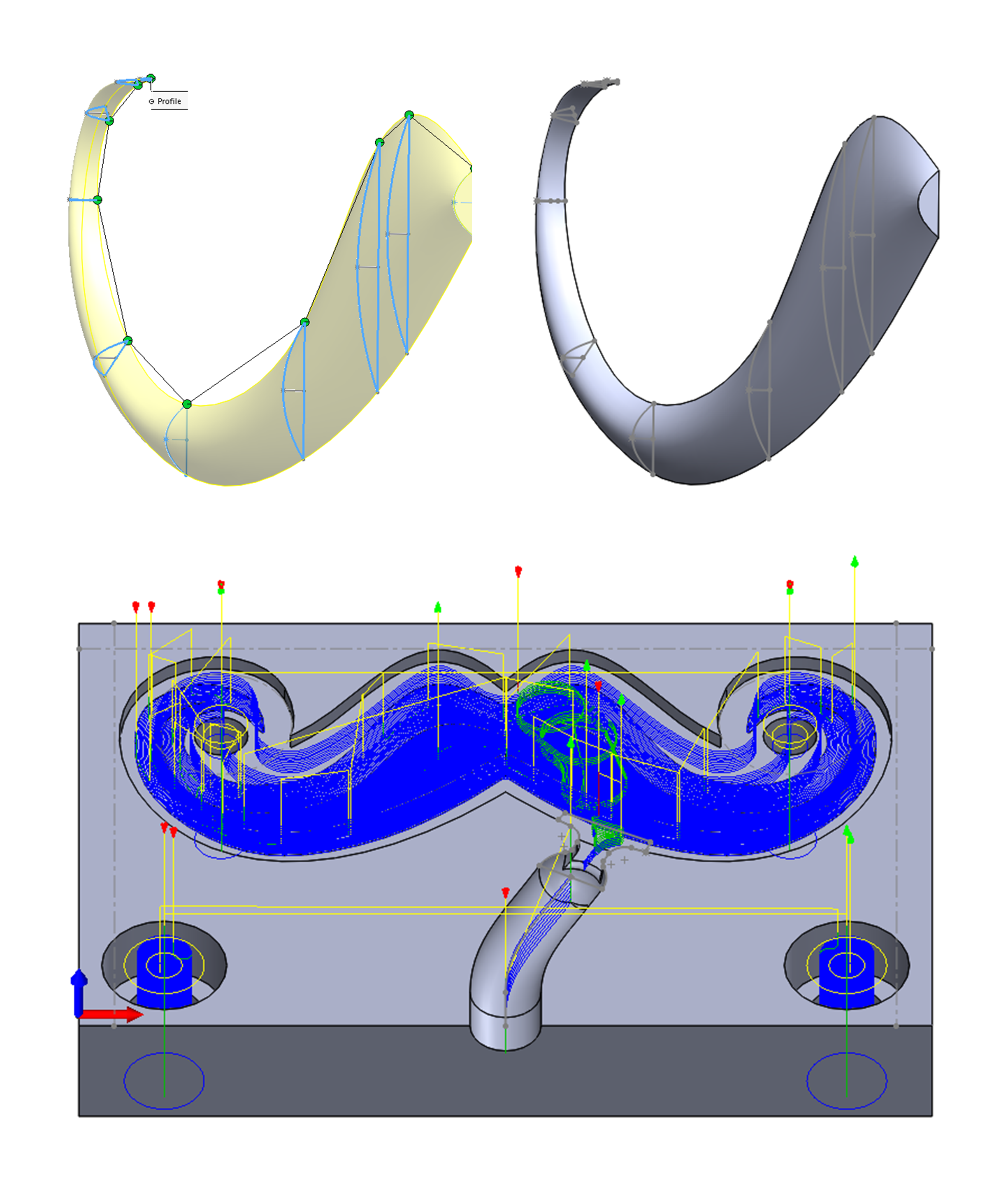

I wanted to use this project as an opportunity to learn the lofting tool in SolidWorks and practice 3D toolpaths on CNC. I designed the Mini Stache to make use of the ejector pin holes as loops in the imperial mustache profile.

From drawing to modeled mold

Lofting to create 3D surfaces, small tool stepover creates fine hair-like toolpaths

Finally Mustached

Course

ME 325: Making Multiples - January 2019

Processes

CNC Milling, Injection Molding

Materials

Aluminum, HDPE